Finally, the day has come when, having messed around for so long, I am hoping to get the rear hubs onto the car at last. I had already purchased some of the new parts required for this momentous day from SNG Barratt many moons ago, as per the table below:

The first operation of the day was to secure the brake shoe mounting blocks to the backing plates using some M6x10 screws with spring washers. I added a dobble of Loctite to these for good measure.

|

| Brake shoe mounting block...mounted! |

My new spacer tubes were inserted to place, the backing plate placed over the hub, and secured using new fixings all around. Each plate needs two M10 screws and two M6 screws; the M10s come with thread lock compound already applied to the threads, I added some extra to the M6 screws. These were tightened evenly using TPS45 and TPS25 bits until the backing plate was snug against the hub carrier. |

| Lower M10 Mounting Bolts with factory applied thread lock |

I then spent some considerable time grappling with the installation of the handbrake shoes and springs (Handbrake Part 1) before it was time to reinstall the hubs.

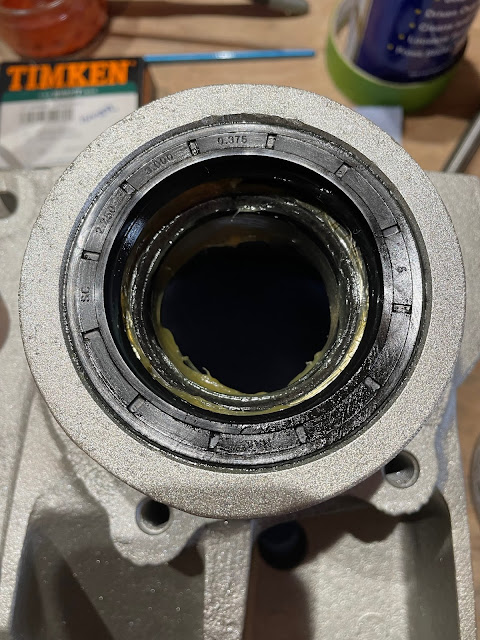

These were given a liberal application of grease before being pushed firmly into place. The hubs were then turned over and the ABS ring tapped onto the back of the hub using a large piece of timber as a suitable drift and a large hammer to provide the force!

|

| Hub greased prior to insertion... |

|

| ...ABS ring tapped firmly back into place... |

|

| ...and one completed hub ready to go onto the car! |

Finally, it was time to get the hubs on the car!

First step - install the hubs onto the lower wishbones. This required the use of two new spacers per hub, which were installed on the face of each of the fulcrum bearings with a good smear of copper grease to hold them in place during installation. I just ordered four new 3.955mm spacers (the same size as my donor spacers) since (according to the AK gospel of Jon Freeman) the shimming / preload of the lower fulcrum bearings is not important so long as the wishbone bracket is pulled tight against the hub. As it was, the new spacers were just about the right thickness, and just needed a gentle tap with a soft mallet to ease the lower part of the hub into the wishbone bracket. I gave all the contact surfaces a light smear of copper grease prior to installation.

The lower fulcrum bolt was given a very liberal application of copper grease, tapped gently through the lower wishbone mount, and secured with an M14 Nyloc and washer - just snugged into place for the moment.

The driveshafts were then installed onto the differential and held in place with plain 7/16 inch nuts. I installed the driveshafts without any shims/spacers between then and the differential flange; the camber will be checked and the required shim thickness worked out next.

The drive shafts were then installed into the hub, which required a bit of manipulation to get the relative angles correct to allow the shaft to slide into the hub, before securing with the original cone washer and drive shaft nut. The cone washer, drive nut, and differential flange nuts will all be replaced with new items once the camber has been set and final shims installed.

|

| Hub and spacers tapped into lower wishbone mount |

|

| The last time I can say it - a heavily greased shaft! |

|

| Differential flange set up with no spacers/shims |

|

| Hub installed - it feels like a major milestone! |

The final finishing touch was to make some plates to cover the hole for the ABS sensor in the top of the hub carriers. Most people seem to leave these open but that just offends my sense of perfection!

I made up a greasy finger paper template, stuck this to a piece of 2mm sheet steel, and cut/filed this down to the required profile. The fixing hole locations were marked out and drilled with a 6mm drill. The plates were of course treated to some candy red powder coating (as with all the other bits that won't be seen on the final car...). I also cut out a couple of gaskets from rubber sheet, to match the outline of the plates, and then these were fixed in place with some stainless steel M6 button head screws with spring washers.

|

| Greasy finger paper template |

|

| Powder-coated plates and rubber gaskets |

|

| Cover plate fixed in place |

A very productive day - time for a well-earned beer me thinks!