So with all the bearing races installed into the rear hubs, the hub pre-load checked, and the correct spacers ordered, now I can crack on with greasing the bearings and finally re-building the hubs, yes?

Actually, yes I can!

Installing the hub bearings is very straightforward and exactly as per the AK Build Manual.

|

| A generous smear of grease applied to the outer race |

|

| Grease vigorously massaged into the outer race |

|

| Even more grease smeared onto front face of bearing |

|

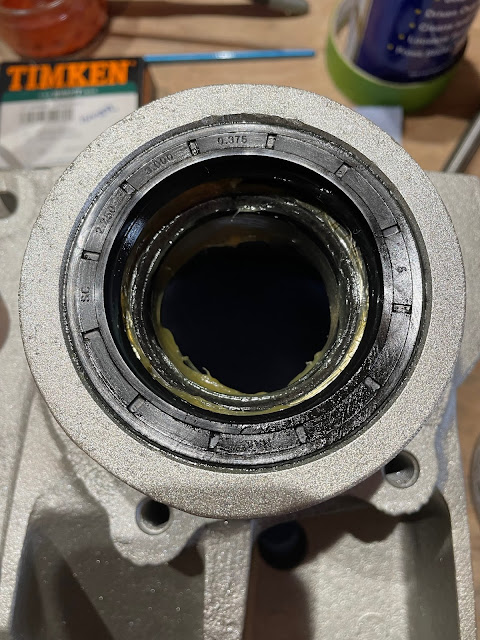

| The outer oil seal was then tapped into place |

It's pretty much the same for the inner bearing, remembering to include the fixed spacer and the correctly sized 3.02mm adjustable spacer.

|

| 3.02mm Spacer freshly delivered from SNG Barratt |

|

| Inner bearing packed with grease and inserted in place with extra grease! |

|

| Tapping inner oil seal into place completes the job! |

Next up is to install the new fulcrum bearings and new pivot pin sleeves. On the original Jaguar set up the fulcrum pivot pin has an eccentric head which engages in a machined groove in the rear wishbone and, depending on the rotation of the bolt head, moves the bottom of the rear hub in or out to set the rear toe-in. This arrangement is dispensed with in the AK set-up.

However there is still a need to install spacers between the fulcrum bearings and the rear wishbone. The AK Build Manual simply states to reinstall with the original spacers from the donor vehicle. All well and good unless, like me, you somehow threw away / lost some of the original spacers when disassembling the rear axle.

All is not lost as you can buy new spacers easily from SNG Barratt or other Jaguar parts suppliers. But, like the rear hub spacer, they come in a variety of thicknesses. Further internet investigation revealed that the rear fulcrum bearings also need to be installed with a certain amount of pre-load. Except that I could find no explanation for setting this up on the later X300 suspension.

I found a few descriptions on various Jaguar forums on how to set the pre-load, but this only seemed relevant to the earlier type hub carriers, which seem to have a two-piece pivot pin sleeve where the spacers are fitted between the two halves of the sleeve. So effectively this adjusts the overall length of the pivot sleeve and hence the distance between the two fulcrum bearings to set the pre-load / tolerance.

I couldn't see a way to apply this method to the later style of hub carrier. The Jaguar X300 Service Manual is not much help either. While it describes the method for determining the pre-load in the main hub bearings very clearly, for the fulcrum bearings it simply says "install equal sized shims to give 0.003in, (0.0762mm) pre-load". It doesn't say how or where....

So I dropped Jon at AK Sportscars a message on this matter. His response was basically not to worry about the preload and just to tighten the outer pivot bolt up enough to pull the ends of the wishbone against the hub carrier. So with that cleared up, I could press on with installing the new fulcrum bearings.

|

| The fulcrum bearings have an integral oil seal |

|

| Bearing given a generous packing with grease |

The fulcrum pivot sleeve sits within a void in the hub carrier. I gave the outside of the sleeve a generous coating with grease to try and delay the onset of any corrosion. I did see a suggestion on one of the Jag forums where someone had drilled a hole from the bottom of the hub carrier into the void and inserted a grease nipple to allow grease to be pumped into the void and allow the fulcrum bearings to be kept topped up, which seemed like quite a good idea. Maybe something I might consider doing in the future.

|

| A light smear of grease on the outside of the pivot sleeve..! |

|

| Pivot sleeve inserted into place... |

|

| ...and fulcrum bearing tapped gently into place |

The hub carrier was turned over and the second fulcrum bearing greased and tapped into place in a similar fashion.

No comments:

Post a Comment