Once the backing plates were reinstalled back onto the rear hub carriers, but before the carriers go back onto the car, it's time to get the handbrake shoes and associated bits fixed in place (I also figured it would be easier to carry out this operation before the hubs themselves are reinstalled).

It goes without saying that for the rebuild I purchased a new set of handbrake shoes for both sides of the car; also if you recall the old shoes had disintegrated to dust when I disassembled the rear axle originally.

I was going to re-use the adjusters and the handbrake levers from the donor car. But after several attempts to try and clean them up, the residual caked-on brake dust seemed reluctant to give up its grip on these parts so I gave in and ordered new parts and new brake shoe springs at the same time.

The handbrake shoes are fixed to the backing plate with a spring-loaded pin; these have a T-shaped end that passes through the backing plate and is locked in place by turning through 90 degrees. Those following the story closely will recall that the T-slots on my donor backing plates (even the replacements from Simply Performance) were shot and I wasn't convinced that there was enough metal left to provide a robust anchorage point for the brake shoe fixing.

That well-known auction site came to my rescue again and I managed to buy a set of replacement pins - these were basically a long M4 bolt with a Nyloc nut. Using three M4 washers per bolt, one on either side of the compression spring and then one between the M4 Nyloc and the backing plate (to further assist in the prevention of the bolt pulling through the backing plate) a suitable replacement fixing was achieved.

My total shopping list for the handbrake rebuild was as per the Table below. I have to admit the cost of the replacement adjusters and levers was slightly eye-watering but at least being brand new parts I can be assured that these will (hopefully) move freely and work as planned.

Advance warning - installing the handbrake shoes is a pig of a job. There seem to be many ways to do it, including the method outlined in the Haynes manual, which frankly, due to the tension in the lower spring, strikes me as impossible! I did wonder whether it would be easier to have actually done this with the hub back on the car, with the rest of the chassis acting as additional ballast to help when trying to stretch the springs; however, for me, I think it was easier (?!) doing this operation on the workbench rather than trying to do it sat on the floor.So this is how I did it (other methods are available).

|

| New parts for handbrake rebuild |

There are six small raised pads on the brake backing plate that the handbrake shoes rest on and the first step was to put a small amount of copper grease onto each of these. You need to take care not to put too much grease on (as with all the following steps) as brake linings and grease do not mix. |

| Location of raised pads on back plate |

I then disassembled the new adjusters and gave the screw threads and recess a generous smear of copper grease. The brake shoes also got a strategic greasing, where the upper and lower tension springs hook into the shoes and also where the adjuster and actuating lever locate onto the shoes. Finally, I put a smear of copper grease on each side of the mounting block on each of the back plates.

With the brake shoes on the bench, I wound down the adjusters to their shortest length, placed them between the tops of each pair of brake shoes, and then inserted the upper and lower tension springs into their respective holes.

I then placed the brake shoe assembly over the hub carrier and onto the backing plate. At this point due to the tension in the lower spring, the bottom of the brake shoes will be too close together to fit either side of the mounting block on the back plate.

There then ensued a short wrestling match as I tried to keep the brake shoes flat against the back plate (to stop the tension springs pinging out of their locating holes) while at the same time trying to pull the bottom of the shoes apart sufficiently to get them to sit either side of the mounting block. Oh and while all this is going on, I was trying to avoid getting all that grease that I had strategically applied to all the contact points ending up getting smeared all over the brake friction material.

|

| And the winner, with two falls and a submission... |

I was pleasantly surprised that once the shoes were in place, the installation of the replacement spring-loaded pins was very straightforward; I anticipated further wrestling to get the holes to all lineup, but everything seemed to line up straight away.I was initially a bit perturbed that the upper tension spring doesn't sit straight and clashes with the adjuster. However the adjuster still seemed to move and the proximity of the spring does have the added advantage that it helps to prevent any rotation of the adjuster cog under vibration, so it's staying as it is!

The actuating levers then received a generous greasing of all the moving/contact surfaces. The new AK handbrake cables were then passed through from the rear of the hubs and fixed into the new levers with the studs from the original levers. Thankfully I had not thrown these away, the new levers do not come with a new stud and the part is not available for purchase.

|

| Lubricated lever and the donor stud for securing cable |

The levers can then be installed between the lower ends of the brake shoes. This needed a bit more wrestling and the gentle application of a small pry bar just to ease the shoes apart sufficiently to allow the lever to drop into place.

|

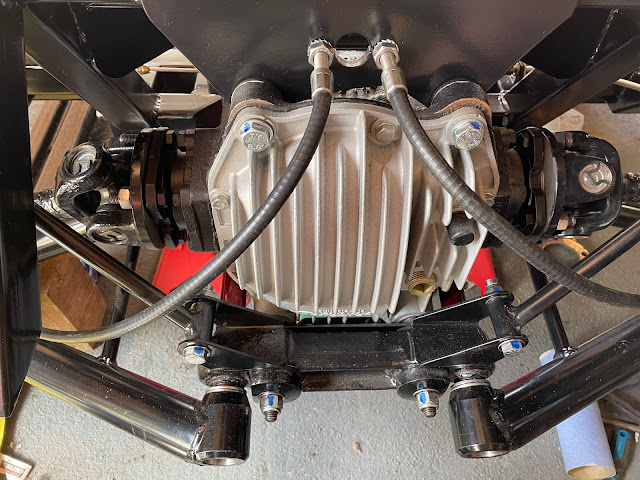

| Completed handbrake rebuild |

Job done - and frankly not one that I would be in a rush to want to have to repeat! Now I can finish off the rear hub installation onto the chassis.