So my power steering issues still need to be fully resolved...

With my pump issues sorted (See Engine & Gearbox Installation - Part 6) all I needed was to connect up the pump reservoir and hoses and all would be good.

Haha...

Having bought the billet ancillaries bracket from Kyle at LSX Performance I knew that I wouldn't be able to use the standard LS Power Steering reservoir which, as I understand it, slots into the standard Chevy ancillary bracketry. Kyle did supply me with an alloy tank to suit the kit he had provided, but in the end, I decided there were a couple of issues with it.

Firstly, the low-pressure spigot on the tank was far too small for the AK-supplied hose and I was worried that I would not be able to get a tight enough seal with a jubilee clip (the AK hose is also braided which restricts the ability of the hose to crush down small enough).

The second issue was that with my shiny header tank and washer tank, the alloy version just didn't really meet my required "bling" standards.

|

| It's good - but not good enough... |

This led me to design my own version of the reservoir which utilised some AN-style fittings that would match the size of the low-pressure hose and the inlet port on my power steering pump. |

| CAD Design for new reservoir... |

|

| ...using -AN weld-on fittings |

I rang around a couple of companies to get a quote for making up my design in polished stainless steel. I ended up going to XCS Designs, perhaps better known for their own Cobra kits, who are just up the road from me. Scott, their Workshop Manager, gave me a pretty reasonable quote on the basis that I provided the AN fittings and a weld-on filler neck (which I obtained from that well-known auction site).

My only real issue with that decision was that XCS was going through a particularly busy period (which is good for them) and I had to wait several weeks before my reservoir was ready. But I think it was well worth the wait!

|

| New shiny reservoir! |

Once I had picked up the tank and was ready to install it, I realised that sometimes it pays to just take a little more time planning and thinking things through fully...

The first issue was that on my original tank, the output spigot at the rear was installed right at the bottom of the tank. In my new design, with the weld-on -10AN fitting, it now sat slightly higher up on the rear of the tank. This meant that the collar of the AN fitting just clashed with the billet ancillary bracket and prevented the tank from sitting flush against the bracket...

|

| Original tank outlet - at very bottom of the tank... |

|

| With weld-on AN fitting, the outlet sits higher on the rear of the tank... |

|

| ...resulting in the collar of the weld-on fitting clashing with the ancillary bracket |

The second issue was that, despite measuring several times, the holes on the new tank did not quite align with the bolt holes on the ancillary bracket. Comparing the hole positions with the original tank showed them to be quite a way off. Again, a stark reminder to plan properly and keep checking everything several times and then check again...

The second issue was actually relatively easy to resolve simply by drilling out the mounting holes on the new tank from 10mm to 12mm diameter with a hole drill. This gave enough wriggle room to get the bolts through the mounting tabs and into the holes on the ancillary bracket. The added bonus was that by allowing the position of the tank to shift slightly, also solved the first issue above, and the tank now could sit flush against the ancillary bracket.

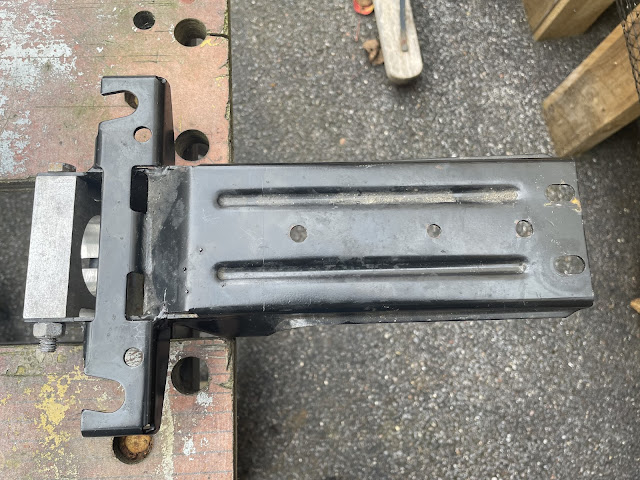

However, the third issue then identified itself. I bought a 90-degree -10AN fitting to attach to the rear of the tank and then connect to the -10AN fitting on the inlet of the power steering pump. However I had failed to consider the dimensions of the -10AN fitting on the back of the tank, and with this installed, there was insufficient space between the front and rear of the ancillary bracket to allow the tank to sit flush as intended.

|

| AN fitting hard against the bracket preventing the tank from sitting flush |

This was not a major deal (although it was annoying) as I was able to turn up a couple of 12mm thick spacers from some 20mm diameter aluminium bar with a 10mm diameter hole drilled through the middle. I also had to buy a couple of slightly longer 10mm diameter bolts to account for the additional thickness of the spacers.

Finally, I could get the tank mounted and the -10AN fitting and braided line routed down towards the pump inlet fitting.

|

| Spacers provide clearance for the rear -10AN fitting |

|

| Tank in place and in need of a polish! |

I used a 150 degree -10AN fitting to connect the hose to the steering pump inlet. I originally bought a 180-degree fitting, but the -10 braided hose is not very flexible and I couldn't get the hose to align with the fitting.

|

| 150 degree -10AN fitting to align with hose orientation |

|

| I needed to angle the hose ends to align with the fitting orientations |

|

| Bottom fitting installed |

The final fitting of the hose was a bit of a wrestling match. The short -10 hose had zero flexibility and the only way I could get both ends onto the fittings was to take the reservoir off again, fit the hose to the reservoir and then try and connect the bottom fitting. Once the hose was secured at both ends, I needed three hands to try and wiggle the reservoir back into place and get the fixing bolts and spacers installed. It was a great relief when everything was finally in place and all bolts and fittings tightened!

The final connection to the reservoir was the low-pressure line return line from the steering rack. This is another braided line supplied by AK. It is installed to the steering rack with a banjo fitting and then routed up to the reservoir. I used a 60-degree -8AN fitting to connect the hose to the reservoir.

|

| Low-pressure return line from Steering Rack completed |

Now all I need to do is get a new high-pressure hose made up with a -6AN fitting on the pump end and this job will finally be done!!!