So with elementary bending and flaring mastered, knocking out the front brake pipes for the Cobra should be a doddle right...?

I started by marking out the positions of the mounting clips and the position of the 3-way brake union on the offside inner chassis rail (all based on my CAD brake pipe routing).

|

Fixing points for brake clips/unions marked using masking tape

|

I started with forming the short pipe that runs from the front off-side brake Flexi to the 3-way union.

I realised at this point that my brake-bending tool was completely useless for this pipe as it is impossible to form a bend on the pipe anywhere closer than around 50mm away from the flared end of the pipe; any closer and the brake fittings get in the way and prevent alignment of the pipe within the bending tool.

I resorted to using a couple of offcuts of nylon sheet with a 3/16 hole drilled through them to hold the pipe in the vice and using a piece of 25mm dia steel bar stock cut down with an angle grinder to bend the pipe around. I checked my bending against a 1:1 drawing of the pipe from my CAD model (sad, I know) and the result was surprisingly close and with the pipe screwed to the Flexi and to the 3-way union the centre of the mounting hole was bang on with my mark on the masking tape. Result! Although this turned out to be a bit of beginners luck...

|

| Forming bends close to brake fitting using a 12.5mm radius former |

|

Checking the bending against CAD drawing

|

|

Pipe in place...

|

|

| ...and mounting hole aligned perfectly with planned position |

Next was the longer pipe run from the 3-way union round to the nearside brake Flexi. This was a step-up in difficulty level from the previous pipe, being just under 900mm long and needing 8 bends of varying angles (from 30 to 90 degrees). This is where being able to position the bends exactly where you want them on the length of the pipe becomes important and brings into play those additional marks on the bending tool.

And just to complicate things, when you form a bend in the pipe, it actually stretches along the outer side of the bend, so the pipe actually gets longer - which of course you need to take account of, to be able to position the bends accurately!

By way of example, the sketch below shows an example length of pipe. Taking the dimensions between the vertices at each bend (the intersection of the centre line of each leg of the pipe) would suggest that the required length of pipe would be 100 + 100 + 70.71 + 60 = 330.71mm.

However, this would not take account of the pipe stretching when forming the bends so the final pipe would not be the exact dimensions required.

There is some complicated method for working all this out but I stumbled across a table in the owners manual for the extremely expensive Swagelok pipe bender on the internet, which has a handy table of bend gain adjustment factors for pipes from 1/8" (3mm) to 1/2" (12mm). Basically, this all boils down that for 3/16" pipe, the adjustment factor for a 90-degree bend is 7mm, for a 45-degree bend is 1mm and for a 30-degree bend is basically insignificant.

Measuring out for the above example would then result in the following:

- P1 would be measured 100mm from the Start of the pipe

- P2 would be measured 100 - 7 = 93mm from P1 (allowing for the previous 90-degree bend)

- P3 would be measured 70.71 - 1 = 69.7mm from P2 (allowing for the previous 45-degree bend)

- The End of the pipe would then be 60 - 1 = 59mm from P3 (allowing for the 45-degree bend as before)

So actual length of pipe to be cut to achieve the final dimensions in the above sketch would be 100 + 93 + 69.7 + 59 = 321.7mm.

(NOTE - that this assumes that the pipe is bent from left to right i.e P1, then P2 then P3 - if you were to bend the pipe in the reverse sequence you would actually have different lengths for various sections - End-P3 (60mm), P3-P2 (69.7mm), P2-P1 (99mm) and P1-Start (93mm) - although the overall length of pipe would be the same at 321.7mm)

So with this exciting theory all worked out, I could take the dimensions of the brake pipe from my CAD model, work out the overall length of pipe needed and mark out the positions of the individual bends making due allowance for the bend gain.

|

| Position of bends marked out |

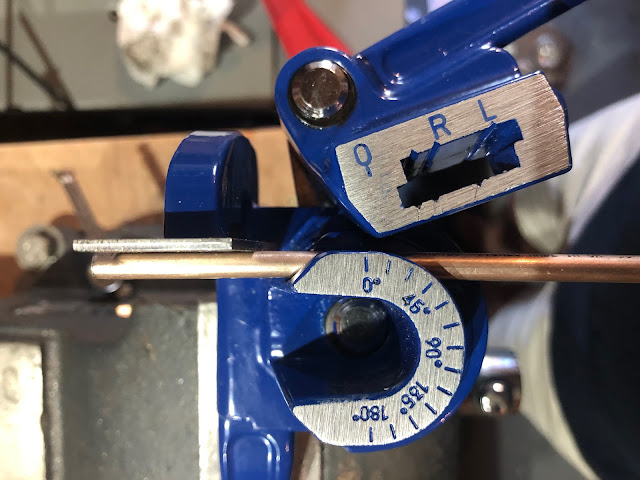

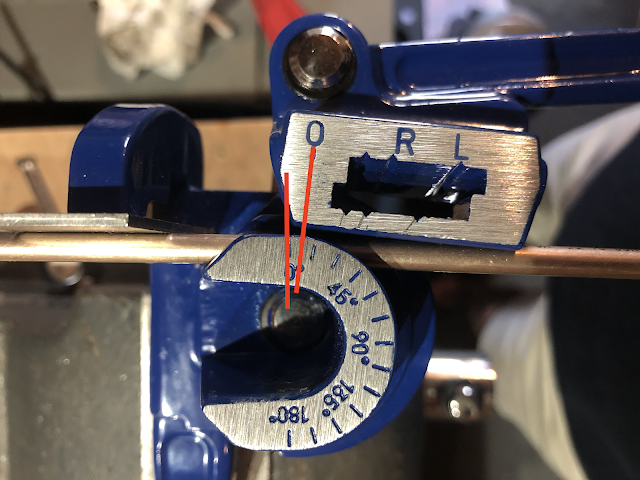

Depending on the required angle of bend, the pipe is positioned in the pipe bender, with the bend position mark aligned with the respective bending mark. The photo below shows a pipe set up for a 90-degree bend - the start of the pipe is to the left side of the tool, so the position mark is aligned with the 'L' on the rotating arm. (If the pipe is inserted into the tool with the previous bend or position mark on the right-hand side of the stop edge then the position mark would be aligned with the 'R'.

|

| Pipe positioned in bending tool - the start of pipe is to the left of the rotating arm so the 'L' mark is used to position the pipe for bending |

|

Perfect 90-degree bend - note I could not perform the first bend using the pipe bender due to the small distance from the pipe fitting

|

|

One section of pipe with perfectly positioned bends (except for the last bend close to the pipe fitting on each end)

|

OK, it wasn't as straightforward as that.

On the first attempt, I failed to follow BRAKE PIPE TOP TIP 1 and produced a perfectly bent-up length of pipe with a brake fitting missing off one end...

Which brings me to BRAKE PIPE TOP TIP 2. Make sure before bending any section of pipe that the brake fittings are on the correct side of the bend as they will not pass over the bend once it is formed - again, you may ask me how I know this...

|

| Hmm...something's missing... |

I think it took about four attempts to get this pipe right and I wasn't helped by my beginner's luck deserting me when trying to form the tight bends needed at the ends of the pipe adjacent to the fittings. My subsequent attempts to form these bends using the method I described above resulted in the bends being too large a radius or just in the wrong place which completely cocked up the alignment of the fittings on the pipe with the fittings to which they were supposed to attach to!

In the end, I had to bite the bullet and bought another set of pipe bending pliers from Frost. These are supposed to form neat bends with a radius of around 15mm with just a twist of the wrist! Well as usual - not quite. You can form bends by gripping the pipe with the pliers and giving it a twist, but it does tend to distort the section of pipe ahead of the bend so rather than being straight, the pipe ends up with a distinct curve in it. Also where the pliers grip the pipe, they left a quite deep gouge which didn't look very professional at all.

|

Eastwood Brake Pipe Pliers - with channels for 3/16" and 1/4" pipe

|

|

Form a nice bend and distort the adjacent section of pipe with a flick of the wrist!

|

My solution was to hold the pipe in the pliers and with both thumbs push the pipe around the bending channel. Hard work on the thumbs but it gave the desired result. A bit more geometry was needed as well to work out the actual start point of the bend to know where to grip the pipe with the pliers.

With this section of pipe now bent up to my satisfaction I could check that the positions of for the brake mounting clips were in the correct place and then drill and tap the chassis to allow clips to be fixed in place. The eagle-eyed will notice that I have powder-coated the backing plates of my brake clips - well I needed to do something to stop them rusting!

|

Final Brake Mounting Clip

|

|

Backplate fixed to chassis with M5 x 8mm Cap-head bolt

|

|

Pipe and Clips in place - nearside...

|

|

...and offside

|

The 3-way union was bolted to the chassis using an M7x30 bolt. The union needed to be spaced off the chassis slightly. Most people seem to use a number of washers to do this but I made up a small spacer from some 12mm dia stainless steel bar, which I drilled a concentric 7mm dia hole down the middle of, and cut off the required spacer thickness.

|

12mm dia stainless steel bar stock

|

|

Pilot hole drilled down the centre of bar stock...

|

|

...before opening up to 7mm dia

|

|

3-way union bolted in place with spacer

|

The final step to complete the front brake lines was to make up the short length of pipe running from the 3-way union to my fabricated bracket. This turned out to be the most awkward section of pipe to make, although if I wasn't so fussy about how neat it should look, it possibly wouldn't have taken so many attempts...

The main issue was trying to form the two 90-degree bends back to back (with one at 90-degrees to the other) adjacent to the 3-way union. The first bend needed to be very close to the union, with the second needing to be right at the end of the first bend. Despite several attempts (more than two but less than fifty...) I couldn't get the two bends to look neat and or get the overall pipe length at both ends.

The purchase of the second set of pipe bending pliers helped somewhat but in the end, I settled for angling the pipe slightly coming out of the 3-way union and making the second bend a 45-degree angle which made things slightly easier to bend.

Which brings me to BRAKE PIPE TOP TIP 3 - when you have had dozens of attempts to make up a section of pipe and finally create the perfect back to back set of bends, do not rush to make the next bend in the pipe and form the bend in the wrong direction from that required...yes you may ask me how I know...

|

| After a couple of attempts... |

|

| ...finally managed to bend up final section of pipe! |

|

Pipe route needs to allow for 1/4" clutch pipe to run between pipe and tube stiffener

|

So that's all the front brake pipes bent up and sorted. I will blow all the pipes through with a compressed air line before tightening up all the unions. Now to bend up the clutch pipe to complete all the pipework at the front end.