My son and I took a quick trip up to Stoneleigh for the National Kit Car Show over the first May bank holiday weekend.

The last year seems to have zipped by; at last year's show we were still doing research before buying our cobra kit and now we are on the early stages of the build.

The show was much busier than last year and it was good to see the AK stand getting lots of visitors!

The main purpose of the visit was to get some thoughts and ideas around future details of the build; colours, dashboard layouts, lights, wheels etc etc.

Unfortunately the visit opened up some very clear differences between my son and I! I am tending towards quick-lift jacks rather than over-riders, he is thinking full bumpers and over-riders. I wanted a classic wooden steering wheel, he wants a modern black wheel. I was thinking classic gauges in the cockpit, he found some horrible digital colour changing gauges (no way!).

It's a good job we have plenty of time before having to make some of these choices!!!!

|

| Lights....modern?... |

|

| ...or classic P700 style...? |

|

| Classic oxblood cockpit... |

|

| Nice grey leather cockpit... |

|

| Or black...? (No wooden steering wheels in sight!!) |

We also had a good wander through the trade stands and picked up some essentials including some abrasive disks, a new set of automatic wire-strippers, a new sign for the garage, some more powder-coating powder and a TIG welder. OK the TIG welder wasn't an essential but I am a sucker for a bargain and it was a show special, half price at £100!

|

| Retail therapy.... |

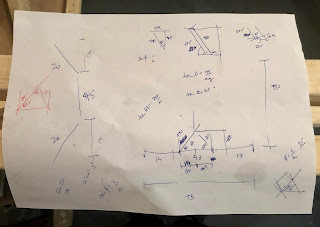

Of course the welder turned out to maybe not such a bargain after all and when I got it home and opened it up it has a strange blue plug on the end of the power lead. Apparently they don't fit a standard 13A socket......and it requires a 32A supply.....and my garage only has a 16A supply.......

Oh well - time to call the electrician!!

|

| Can't get that into a normal socket!!! |