However, the change of my blasting media of choice from kiln-dried sand to aluminium oxide soon identified a major issue.

The aluminium oxide media is far more abrasive than the sand; so abrasive that it actually blew its way through the nozzle of Budget Blaster. I was starting to notice that it was taking a bit longer to clean off one of the rear hubs and then I spotted the hole in the nozzle...

|

| The additional hole does not improve performance..... |

OK I thought, I've managed to do quite a lot of sand blasting with the original nozzle so I'll just order another set of nozzles from a well-known mail-order company that offers next day delivery and that should see me set for a bit longer. In the meantime, I'll just revert to Budget Blaster Mk1.

A great plan....for less than 5 minutes, by which time Budget Blaster Mk1 had bitten the dust as well.

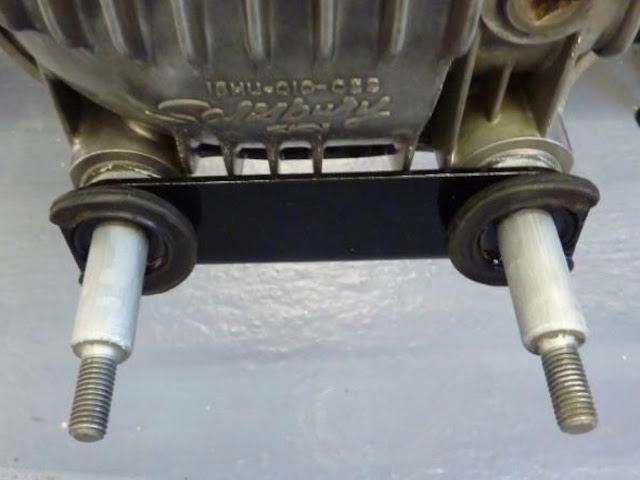

|

| RIP Budget Blaster Mk1... |

Clearly, the nozzles were not going to survive very long with the aluminium oxide media and so I cancelled the order for another set of cheap nozzles and contemplated Plan B.

Plan B involved the purchase of a Clarke SB3 Grit Blasting Gun, the main lure of which was it came with a hardened steel nozzle! There were fairly mixed reviews of this on the internet, but for £20 I was prepared to give it a go.

|

| Clarke SB3 Grit Blast Gun - photo courtesy of MachineMart |

Some of the reviews cited issues with media delivery and volume of media used. I found one review that said to ensure the delivery tube was fixed facing forwards and to angle the gun downwards in use - which I did and had no problems in use.

However, the speed at which the gun uses blasting media is quite high. The pot takes has a litre capacity so around 1-1.5kg of media. My initial experiments with the gun managed to empty a full pot in a couple of minutes. The results were impressive but clearly, some means of capturing and recycling blast media would be required otherwise 25kg was not going to last very long!

My solution was to buy a large tarpaulin and a cheap gazebo with sides, from the well-known internet auction site, to make a supersize blasting 'cabinet' by laying the tarpaulin on the floor and sitting the gazebo on top. The theory being that the gazebo would help to contain the excess blast media and this could be swept off the tarpaulin and reused.

For the first full-scale test of this set-up, I reverted to using the kiln-dried sand since a) the damp bag that I bought previously had now dried out a bit and b) if the set-up failed I was only wasting a £3 bag of sand rather than expensive aluminium oxide.

I have to say the results using the SB3 gun and sand were pretty amazing. The gun is pretty effective and I managed to strip and clean some of the rear axle parts in less than 30 minutes. It does go through the media at a phenomenal rate! But the tarpaulin/gazebo combo did a reasonable job of containing the excess media and with some frequent sweeping up, I did manage to recycle a fair amount of the sand and finished with almost as much as I had started with!

|

| Lifes a Beach - After 5 minutes of blasting... |

|

| Initial results... |

A quick blast with the aluminium oxide should see these parts finished and ready for powder coating.

So a big thumbs up for Plan B (although unfortunately, the 'B' does not stand for budget...)