The budget sandblaster has been busy - now powered by my new 3hp /100-litre air compressor, which was a present to myself for a recent major milestone birthday.

|

| Bigger is better! |

I also have also tried out some different blasting media.

I was quite happy with the results using the Wickes Kiln Dried Sand; well at least with the first bag I had bought. When I bought the second bag, the sand was more like builders sand, quite soft and slightly damp, and just clogged in the nozzle of the blaster.

So I splashed out on 25kg of Fine Glass Grit from Amazon and 25kg of Fine Aluminium Oxide from Frost.

I have had some great results with the aluminium oxide. It strips paint, rust and clag off in next to no time. It's far more brutal than the sand, both on the metal parts and on exposed skin!

|

| Aluminium Oxide blasting media |

The glass grit is a more gentle blasting media and is good for removing light rust and cleaning up the machined surfaces of some of the donor parts.

|

| Fine Glass Grit blasting media |

HEALTH AND SAFETY TIP - As with the sand it is important to wear eye protection but I found it necessary to upgrade to a full set of enclosed safety goggles (after learning the hard way that aluminium oxide grit is very sharp and will find its way into your eyes while just wearing an ordinary pair of safety glasses). Also with both the aluminium oxide and glass grit, I would recommend a good quality dust mask; both media have a lot of very fine particles which I have no doubt are not good for the respiratory passages.

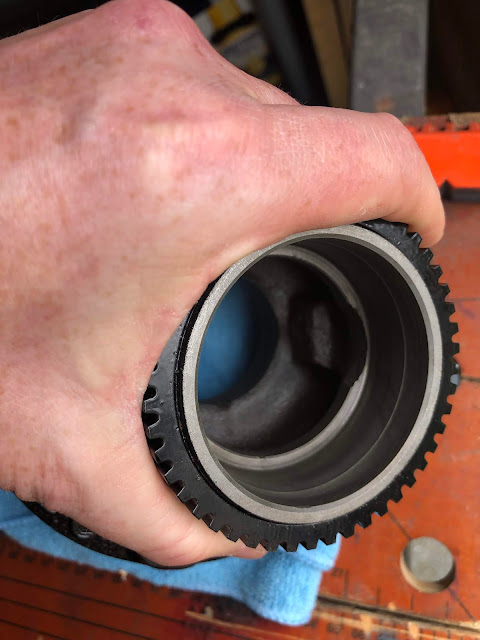

The pictures below show one of the rear stub axles before and after blasting. The aluminium oxide cleaned off all the old paint in less than 10 minutes (the kiln dried sand would have taken over an hour) and then I used the glass grit to clean up the splined shaft and threaded end of the shaft.

|

| Prior to a good gunking! |

|

| Post gunk...(zip ties used to identify parts from offside driveshaft) |

|

| After 20 mins of the budget blaster with Aluminium Oxide / Glass Grit media |

After my problems with the front hubs and the development of further rust/corrosion between blasting and powder coating, I decided to try out Eastwood's After Blast Metal Prep.

|

| A gallon of SlartyAfterBlast... |

This stuff is supposed to clean and degrease freshly blasted metal and also contains phosphoric acid to etch the metal surface and leave a zinc phosphate coating to prevent flash rusting and give a good surface to aid adhesion of paint or powder coat. It's not cheap, at £45 a gallon from Frost, but if it does the job and saves me sandblasting everything twice, then I guess it will be worth it.

I bought a cheap spray bottle and used it to spray the parts with the After Blast. The instructions say to leave it for 2-5mins and then to wipe off with a clean cloth to remove any excess contaminants and excess spray.

|

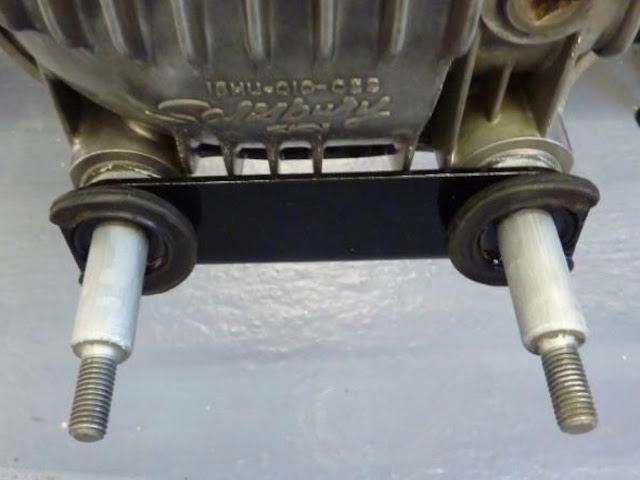

| The inboard Drive Shaft Saddle after After Blast treatment... |

A couple of tips for using this stuff:

1) Do make sure any excess liquid is wiped off - if it's allowed to sit on the part it develops into large blobs of zinc phosphate coating

2) Avoid machined surfaces - since the spray etches the surface of the metal you want to avoid getting any spray on these surfaces and it will change the surface texture (i.e it's no longer smooth and machined!)

I made these mistakes the first time round on one of the inboard driveshaft saddles and ended up having to clean up the areas with a brass wire wheel in the angry end of the drill.

But the stuff does seem to work - I blasted the inboard driveshaft saddle a couple of weeks ago and no further rusting / corrosion had developed by the time I got round to powder coating.

Below are a few pictures of various parts in preparation and after powder coating.

|

| Rear Hub and Stub Axle prior to blasting |

|

| The backside of the Rear Hub after blasting... |

|

| ...And the front face |

|

| Hub getting an After Blast bath (avoiding the machined surfaces) |

|

| Inboard Driveshaft Saddle fresh out of the oven |

|

| Freshly coated Hub and Drive Shaft ends |