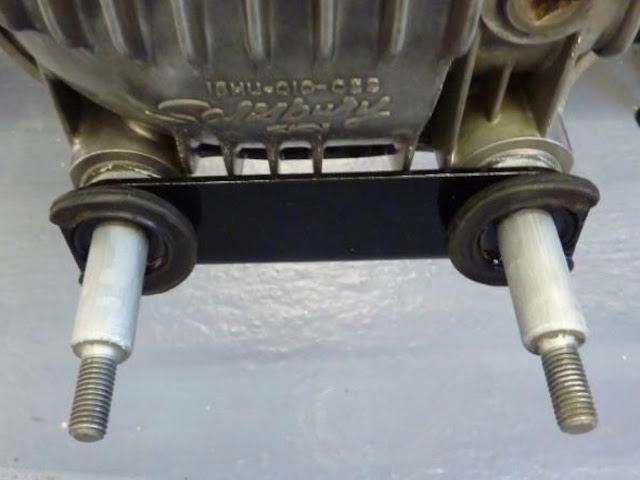

First up was to install the donor mounting bracket, which is simply slid over the main rear differential bolts.

|

| Wishbone tie (top), Mounting Bracket (middle) and Compliance Buffers (bottom) |

|

| Mounting bracket installed... |

I then applied copper grease liberally to the main rear diff bolts and installed the inner compliance buffers (the ones with the big hole which fits over the main bolts); these are installed with the flat edge towards the outside of the chassis.

|

| Inboard Compliance Buffers installed... |

All nice and straightforward so far!

Next on was the wishbone tie; this is installed with the side marked "Jaguar" facing towards the rear of the chassis.

|

| Wishbone tie in place - I see a problem looming... |

The outer compliance buffers are then installed again with the flat edge facing outwards.

Hang on! There's no thread of main rear diff bolts protruding out of the assembly to get the M12 Nylocs onto! WTF!!

|

| Bugger...! |

After much head-scratching, drinking of tea, internet research, taking it all apart and reassembling (hoping for a different result), and a teeny bit of swearing, I was none the wiser and I still had no protruding thread onto which to attach a nut...

The problem it seemed was simple; the flange on the back of my compliance buffers seemed to be too thick/big to allow the buffer to sit tightly against the wishbone tie.

|

| This doesn't look right... |

Then I remembered something fellow builder Richard had said to me when he was round and I had shown him some of my first attempts at powder coating; which happened to me a couple of the metal compliance buffers. Richard had said that his buffers/spacers were completely different; they were rubber with a metal insert.

So I had a closer look at the AK Build Manual and the buffers/spacers in the photo in the manual looked completely different from mine.

|

| These are not my spacers! - Photo courtesy of AK Sportscars Ltd |

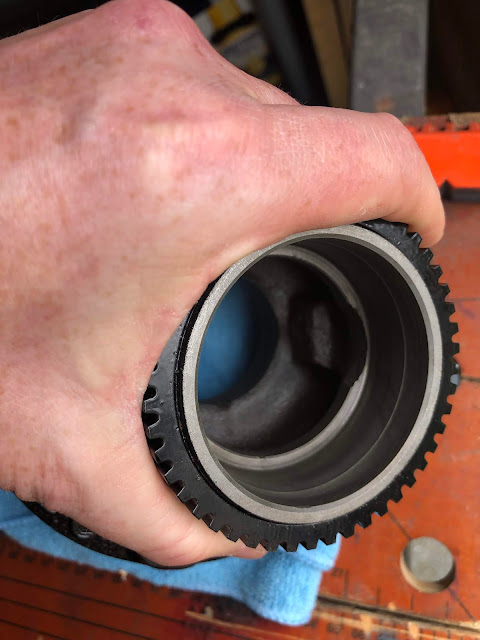

Then I had a lightning bolt moment and I dug out the original wishbone tie that I had received from Simply Performance with my donor axles; remember the one that I had assumed was missing the inner bushes.

Well, guess what - the flange on the back of my metal buffers/spacers seated exactly into the recess in the wishbone tie where the inner bushes should have been fitted.

|

| Fits like a glass slipper! |

A quick email to Jon at AK and he confirmed that some of the Jag rear ends did come with a solidly mounted wishbone tie. So it was a good job I kept the original wishbone tie and even better, I had decided to powder coat it as well! (Although the finish was not as good as the tie that I thought I was using - so I might need to consider recoating it at some point).

Armed with that knowledge, I tried reassembly with the original wishbone tie, and this time it all went together beautifully and I ended up with a goodly amount of thread from the main rear diff bolts sticking out to get the M12 Nylocs and washers onto.

|

| Looking more promising... |

|

| Result! |

So after several hours attempting a job that should literally have taken five minutes, I need a lie down...or a beer...or both!