Before bolting the gearbox up to the engine I had a couple of modifications to make to the GM hydraulic throwout bearing.

The first was to replace the factory inlet fitting with one that would allow me to connect up a -4 flexible braided clutch line. This was a simple task of drifting out the roll pin securing the fitting, removing the original fitting and replacing it with a new one from Summit Performance. To complete the job, I secured the new fitting with a new 4mm roll pin.

|

| GM Hydraulic Throwout Bearing with original fittings |

|

New -4AN inlet fitting (top) vs original inlet fitting

|

|

| New fitting installed and secured in place |

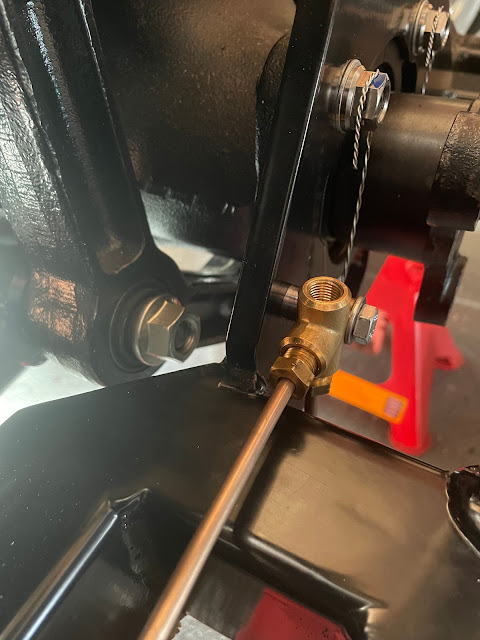

Next up was to replace the factory bleed fitting with a HEL flexible braided remote bleed line. The original attachment was unbolted very easily and it was a simple matter of screwing in the new remote bleed line with a copper washer and tightening it down firmly. Now I can bleed my clutch without a) any special tools and b) without having to faff around under the car; the end of the remote bleed line will be fixed somewhere suitable in the engine bay.

|

| Remote bleed line installed |

I ordered a braided clutch line from Merlin Motorsports which they made up to a length of 500mm and installed the fittings for me free of charge. I installed this onto the new -4AN inlet.

|

| Braided -4 clutch line installed |

The throwout bearing could then be bolted to the front of the gearbox, over the input shaft and with the two M6 securing bolts torqued to 35ft-lbs / 47.5Nm.

|

| Throwout bearing installed on the gearbox |

Just as I was preparing to fix the bellhousing to the engine, life decided to throw me another curveball. In between the various tasks I had been keeping the engine hanging off the engine crane, but lowering it down to the floor in between jobs. I didn't put the whole weight onto the floor, it was 'just' resting on some thick cardboard packing to protect the sump but most of the weight was still being taken by the crane. In the event of any failure of the engine crane, I figured it was better to be closer to the ground than hanging in mid-air.

And then that failure occurred!

The engine crane I had borrowed was a mechanical rather than a hydraulic unit. Raising or lowering the jib was achieved by hand turning a nut on the end of a long threaded rod which passed through a fixed threaded anchor block.

As I was merrily turning away at the nut with a ratchet to raise the engine up to install the bellhousing, I realised that while the nut was happily turning around, the thread in the anchor block was not moving at all. In other words, I was perilously close to shearing the nut off the end of the threaded bar and dropping the engine fully onto the floor.

|

| Coming close to disaster... |

There then followed a short interlude while I endured the unexpected expense of buying a new 2T engine hoist from Halfords, waiting for delivery and then having to assemble said crane.

With some help from my son, we managed to get some additional thick pieces of cardboard packing under the front and back of the engine, such that it was fully resting on the packing. This gave enough slack to be able to unbolt the shackle holding the lifting chains to the original crane, whip it out of the way and swing the new crane quickly into place and attach engine chains to the new crane. Hopefully, the only damage that I can see was caused when I rocked the engine slightly to one side to help hook it onto the new crane and dented the bottom of the oil filter.

With disaster averted I could now get on and install the aluminium bellhousing to the engine. This needed tapping gently into place over the two locating pins on either side of the rear of the engine and then bolting up, tightening the bolts in an alternating sequence up to 35ft-lbs / 47.5Nm. The fixing kit from Roadcraft came with M10 bolts for fixing the gearbox and bellhousing but also included two rogue M10 Cap Head bolts. There are two positions on the bellhousing where the casting is such that clearance is very limited to get a 17mm socket over the end of a normal M10 Hex Head bolt so I assumed that was where the cap head bolts were to be used and these were tightened using an 8mm Allen-drive socket.

|

| Bellhousing installed |

Then it was just a simple (?!?!) of joining the gearbox to the engine...

As with most things on this build, this was not as simple as it should have been. I placed the gearbox on a wheeled wooden dolly and adjusted the height of the engine so that the gearbox input shaft was level with the centre of the clutch alignment tool. I pulled out the alignment tool and then moved the dolly forward to engage the input shaft into the clutch plates. This took a bit of jiggling to get the splines on the input shaft to align with the clutch plates. With a bit more jiggling I could then get the transmission to within about an inch of the bellhousing but couldn't get it to close up that last bit.

|

| Almost there... |

Over the course of the next 6 hours of wrestling with a 60kg lump of metal, I taught myself some new swear words as I repeatedly removed and tried re-engaging the gearbox into the clutch but still couldn't quite get it to fully join. I even persuaded my son to help out, but the gearbox continued to defy us!

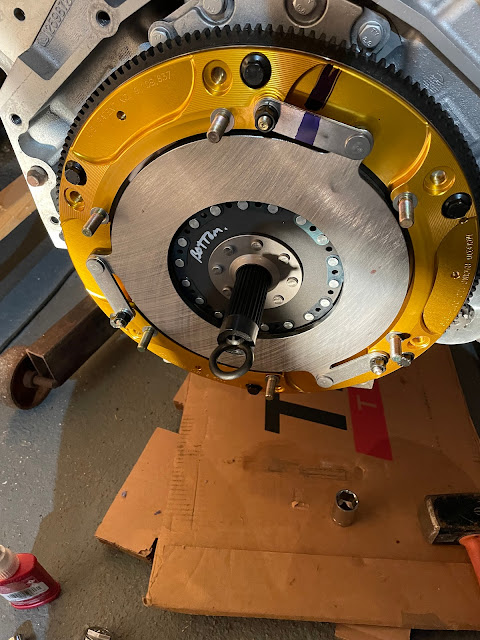

Eventually, I decided that, because of the twin-plate clutch, the alignment needed to be absolutely spot on to allow the gearbox input shaft to engage in the pilot bushing. So I pulled off the bellhousing, removed the clutch pressure plate and realigned the clutch plates. This time I retightened the pressure plate bolts a couple of turns at a time in an alternating pattern to try and keep the clutch disks centred before torquing down to the final specification. This did result in the alignment tool sliding in and out of the plates more freely than previously.

The next morning I renewed the battle, and after only a couple more rounds of wrestling, finally managed to get the gearbox to mate up with the engine! I could then install the bolts to hold the transmission to the bellhousing and tightened them up to 35ft-lbs / 47.5Nm. There was a small bracket on the gearbox breather hose, which I made sure to remember to secure with one of the transmission bolts.

|

| Success at last! |

|

| Bracket holding breather hose |

|

| The rear transmission mount fixed in place |

The last job before actually installing the engine and gearbox into the chassis was to reinstall the starter motor. I had removed this to wrap it in some gold heat reflective tape from Funk Motorsport. This should protect the starter motor from the heat from the exhaust headers and avoid any electrical issues due to heat soak

|

| Starter wrapped in heat reflective tape |