So if you hadn't already guessed, I am now planning on installing an LS7 engine instead of the LS3. My engine builder, Kyle, made me an offer I literally couldn't refuse. He also persuaded me to consider dry-sumping the motor to eek out a few extra horsepowers - hence the need to try and find a location in the confines of the AK for a remote oil tank.

So the revised engine specification looks a bit like this

- LS7 Pistons - Mahle PowerPak Forged 4032 Alloy for low expansion with Grafal anti-friction skirt coating - modified wrist pins - hot washed and checked

- Mahle High-Performance Piston Rings

- Compression Ration approx 11.3:1

- Competition Cams Camshaft (guaranteed to pass IVA / MOT)

- Competition Cams reduced travel Hydraulic Lifters

- Competition Cams Rocker Trunnion Upgrade (with needle roller bearings)

- LS7 Titanium Conrods

- ARP High-Performance Big End Bolts

- Clevite H-Series Big End and Mains Bearings -

- MLS Head Gaskets

- Double Valve Springs

- Uprated Water Pump

- New Front Damper

- LS7 Sump Pan with adaptor for -12 oil lines to remote tank

- New LS7 Intake with 42 lb per hour Injectors

- One Piece Manley Pushrods

- New Gaskets

- New Sensors

- New Oil Seals

- Fly-by-Wire Throttle Body

- Custom Corvette Front End (Power Steering Pump, Alternator, Idler and Custom Tensioner)

- Canems ECU and Wiring Loom modified to include immobiliser

- Dyno Run and Set-up

Kyle started pulling together all the parts for the engine earlier this year but the Covid-19 pandemic caused a few delays with some of the parts coming from the States so final assembly did not begin until mid-June

|

| Pistons and Rods ready for assembly |

|

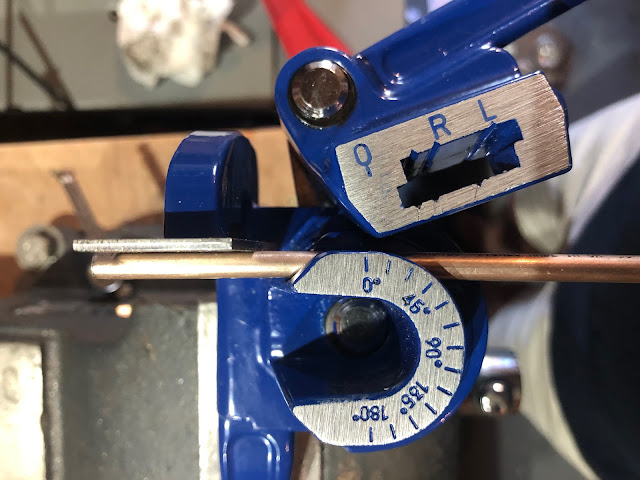

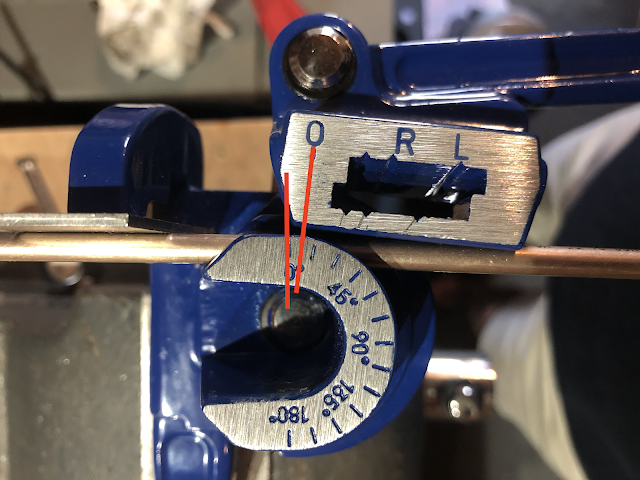

| Piston Ring Gapping |

|

| Short Block Assembly complete |

|

| Cylinder Heads - CNC Ported / 70cc Chambers - 2.205in dia Titanium Intake Valves & 1.610 in dia S/Steel Sodium Filled Exhaust Valves |

|

| Uprated Valvetrain |

|

| Fly-by-Wire Throttle Body |

|

| Sump Adaptor to connect to remote Oil Tank |

|

| Assembly almost complete - looking like an engine! |

The stock LS7 produced a respectable 505bhp at 6300rpm and 470lbft torque at 4800rpm. Kyle built the LS7 for Apple, the AK demonstrator, which put out around 630bhp and a shade under 600lbft torque, some serious gains over stock, and I would have been happy with similar numbers from my engine.

Kyle had the engine hooked up to his dyno at the beginning of July and spent a day checking over for leaks, before a session at fast idle to run in / bed in the engine. The plan was for Dave from Canems to come and assist with the set-up of the ECU before carrying out the power pulls proper.

About mid-day on the day that Kyle was hoping to do the power pulls, I got a phone call. "Are you sitting down?" he said. So down I sat, thinking the engine had blown up on the dyno or some other equally catastrophic scenario. Turned out the numbers on this beast exceeded even Kyle's expectations; 659bhp at 6300rpm and 603lbft at 4900rpm! He was over the moon and so was I!

While the engine was still on the dyno I took the opportunity to pop up to Kyle's workshop and check it out in action. It also gave me the chance to familiarise myself with all the various connections from the ECU to the engine sensors and to get some guidance from Kyle for when I come to start up the engine myself.

The video above of the outside of the dyno room just does not convey the power of this engine - it was like a Force 8 gale blowing out of the exhaust pipes and the whole ground was shaking. Absolutely awesome piece of kit and I would recommend Kyle without a doubt to anybody wanting to get some serious bang for their buck on the engine front.

I should be picking engine up in a couple of weeks time so I guess I'd better crack on with getting the rolling chassis completed!!