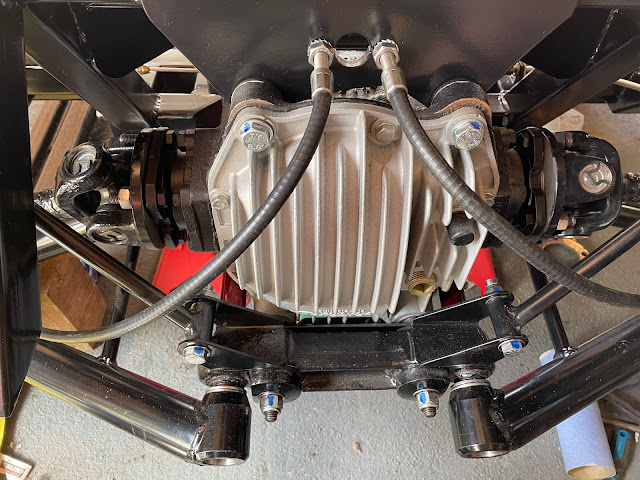

There were a couple of small jobs that I needed to do to complete the installation of the rear differential.

The first was to cut down the 7/16UNF bolts securing the tie bars to the differential and the chassis. The threaded length of these bolts is much greater than actually required and the protruding length looks a bit odd (to me anyway).

The second was to actually torque up all the various differential mounting bolts. I didn't do this at the time of the original installation as, quite simply, I couldn't find the details for the necessary torque settings.

|

| An offensive amount of bolt sticky-outedness... |

I reckoned about 10mm off the end of the tie bar bolts should suffice. Before cutting I wound a 7/16UNF die onto the bolt a) so that I could make sure the threads were intact after cutting and b) it made a handy brace to help support the bolts in the vice while cutting!

|

| Die used to help keep bolt in place while cutting |

I cut down the bolts with a hacksaw and then reinstalled them into the tie bar mounts, with a further liberal application of copper grease, adding a 7/16 washer on each end and 7/16UNF Nyloc nuts. The final result was far more pleasing to my eye!

|

| Much better - no unnecessary protrusion! |

Now to finish tighten up all the differential mounting bolts. You would have thought it would have been a relatively simple task to find all the necessary torque specifications, but oddly enough it took me a fair bit of searching before I was sure I had the right values. This is complicated slightly by the fact that the AK mounting arrangement for the differential is of course not quite the same as the original Jaguar arrangement but my research was also hampered by the various Jaguar service manuals not calling any of the parts/bolt descriptions by anything remotely helpful!

No comments:

Post a Comment