I have just realised that it is also just over a year ago that my AK body/chassis kit was delivered. So it seems like a good point to take stock of where I have got to in the build process.

I also recently discovered that my kit delivery date of 11 January (2019) is the same date as Carroll Shelby's birthday (11 January 1923). An interesting coincidence!

As it currently stands, I have not made as much progress as I would have liked. The front suspension/axles are complete (minus brakes) but at the rear, I have only got as far as installing the differential. I had hoped to be at rolling chassis stage by this time. |

| Delivery Day - 11 January 2019 |

|

| Front axle complete except for brakes |

|

| Rear Differential Unit in place |

I have got a lot of the parts for the rear axle prepped and ready to install. My decision to prep a lot of the parts myself (home sandblasting and powder-coating) took a lot longer than I anticipated (but hopefully saved me a bit of money and added to the satisfaction of doing as much as I can myself).

|

| Rear axle components prepped and powder-coated ready for re-assembly |

I have also not really had many opportunities to do much on the build since my last post back in October 2019. Many things contributed to this. Work went a bit mental back in the autumn and I spent quite a few weekends having to work rather than play! We also had some work done on the house (which is still not fully finished), having most of the downstairs floors replaced. This meant clearing out the contents of all the rooms and a lot of this stuff found its way into the garage, with the result that working space and access to anything was severely hampered.

Even when I did find some time (and make some working space) I found myself thwarted by some unforeseen issues. I bought myself a 3HP compressor with a 100-litre receiver back in the summer; this performed faultlessly during all the sandblasting that I was doing at the time.

|

| New compressor - doesn't like the cold... |

When I came to try and use the compressor in late autumn, it would not start. There was a brief humming from the starter before it blew either the fuse in the plug or tripped out the garage power supply!

I was worried that the starter capacitor was faulty. But after the usual extensive internet-based research, it seems that 3HP is right on the limit of what a domestic electricity supply can provide, especially if the plug is at the end of a long run of cable (such as a garage). Also during cold weather, the overall demand can affect the actual voltage supplied. Additionally, as the temperature drops the viscosity of the oil in the compressor motor increases. The result of these factors is that, in colder conditions, the compressor motor can not produce enough power to overcome the higher viscosity of the oil and effectively stalls (and blows the fuse).

This can be overcome by heating the compressor oil (using a strategically applied heat gun) but took a long time (and spare fuses) before I managed to coax the compressor to turn over. Hence not a practical solution for trying to do some quick jobs...

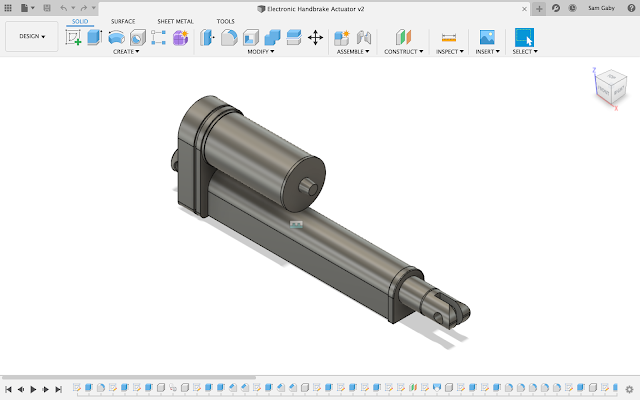

Time has not been wasted though. I have been doing some planning of the next stages, including the brake and fuel line routing and fixing (no ordinary P-clips will be used in this build!) and I am also toying with the idea of utilising an electronic handbrake based on a 12V linear actuator.

|

| Starting to mock-up handbrake set-up in CAD |

The next list of jobs to do are:

- Extract broken screws from one of the rear hubs;

- Clean and powder-coat ABS rings from rear hubs (these hold the rear axle stub in place);

- Reassemble rear hubs;

- Install new universal joints in driveshafts;

- Install hubs/driveshafts and rear wishbones;

- Install rear shocks;

- Cut down rear brake backing plates and powder-coat;

- Install handbrake shoes and springs in hubs.

The other main development in the progress of Project Snake has been the engine. My original plan was for a Chevy 6.2L LS3 motor. This was going to be built by Kyle Rushall. Kyle and I have been exchanging texts over the past few months about the exact specification of the motor I was after. In the end, he offered me an alternative engine at a price that I couldn't really refuse.

I'm going to leave you all hanging for the moment as to the final spec, but it will be a 427 cubic inch engine (but not a Ford...), it has titanium con-rods and I need to find somewhere in the confines of the AK body/chassis to locate a dry-sump tank...

|

| A titanium rod - 464 grams compared to over 600 grams for a steel rod |

Kyle has started prepping the block and heads. The engine build should commence around the end of January and is due for completion sometime in March 2020.

The downside is that the new engine is a "bit" more expensive than I had previously budgeted for so I need to rethink spending plans for the next stages while I save up!

No comments:

Post a Comment