My plan for the engine is to use a Chevrolet LS3 engine with a Tremec TKO600 transmission.

My original thought was to buy the engine and gearbox as a complete package from Brian at Roadcraft UK Ltd. Brian had given me a quote based on the 430hp version of the GM LS3 Crate Engine with all ancillaries and ECU.

I would have preferred the 525hp version of the LS3 Crate Engine, but from reading on the various internet forums it seems there is no chance of this engine passing the IVA emissions test.

At the end of last year another AK Cobra Builder, Barry Boughton, had contacted me after reading my blog. He recommended the name of a guy, Kyle Rushall, who had built his LS7 engine and also apparently built the engines for Apple and Rufus, the AK Demonstrator vehicles. I've been in Apple and I can testify to the power the engine in that beast puts out!

Turns out that Kyle used to work at Tim Adams Racing Engines and has built quite a few engines for the Cobra community. He is now working on his own and building engines for the GT and Drift scene amongst others.

I made a mental note to drop him a line, but figured that getting a bespoke engine built was always going to be more expensive than buying a crate engine package and never really got round to it. Besides I was planning on spending the rest of 2019 getting the rolling chassis completed and didn't think I would be in a position to need the engine/transmission until early 2020 at best.

Anyway a few weeks ago I saw an advert on Fleabay for an LS7 engine; the price was out of my range but the seller was also offering LS3 engines. I sent a message asking for prices and it turned out the seller was none other than Kyle Rushall himself!

He suggested I give him a call to discuss options, which I did and we had a good chat through things. Turns out he has built a few LS3 engines for Cobra builders now; the last one made over 560hp and passed the IVA test! Not only that but the price he quoted was not a million miles away from what Roadcraft UK was quoting.

Unfortunately, Kyle only has two LS3 cores left and is not expecting to get any more until late 2020. So after some brief (?!) negotiating with my better half, I have altered by budget plans and put down a deposit to secure one of the remaining cores.

- LS3 Pistons - hot washed and checked

- Mahle High Performance Piston Rings

- Custom Camshaft (not too aggressive grind - but guaranteed to pass IVA / MOT)

- Competition Cams reduced travel Hydraulic Lifters

- Competition Cams Rocker Trunnion Upgrade (with needle roller bearings)

- LS3 Conrods

- ARP High Performance Big End Bolts

- Clevite Big End Bearings

- Clevite Mains Bearings

- MLS Head Gaskets

- Double Valve Springs

- Melling Oil Pump

- Uprated Water Pump

- New Front Damper

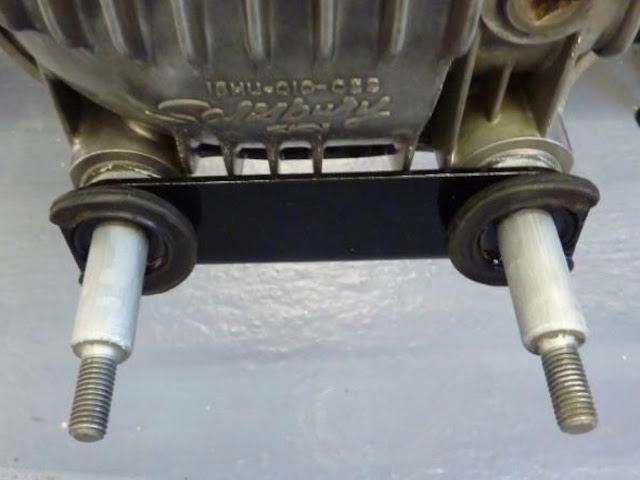

- New F-body Oil Pan (to fit AK Chassis)

- New LS3 Intake with 42 lb per hour Injectors

- One Piece Manley Pushrods

- New Gaskets

- New Sensors

- New Oil Seals

- Fly-by-Wire Throttle Body

- Custom Corvette Front End (Power Steering Pump, Alternator, Idler and Custom Tensioner)

- Canems ECU and Wiring Loom

- Dyno Run and Set-up

Kyle is a busy man and engine won't be ready until later this year, which is fine for me as I still have a way to go to get rolling chassis completed.

|

| I'll have one of those please! (Photo courtesy of Kyle Rushall) |