Back in the good old days, a manual gearbox was a simple matter of some magic mechanical coggery hidden in a case, with an input shaft, an output shaft and some sort of shifting mechanism to change between the (then four) gears.

Clearly, things have moved on, and not just in the number of available gears. After unboxing my Tremec T56 gearbox I noticed a number of electrical connectors dotted around the casing. After some internet research, I discovered the following:

The connector at the front left-hand side of the gearbox casing is for the reverse light switch i.e it activates the reverse lights when reverse gear is selected.

|

| Reverse Light Connector |

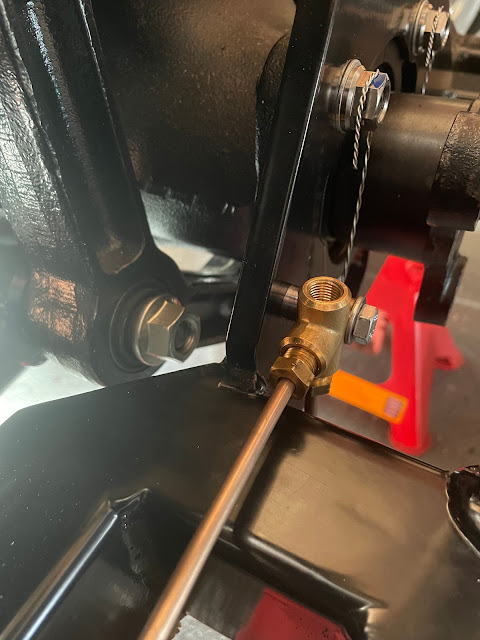

The connector at the rear left-hand side of the casing is the VSS output (variable speed sensor) which is used to send a signal to an electronic speedometer (there is also a mechanical speedometer output on the opposite side to the VSS connector - as I will be using the VSS option the mechanical output needs removing and replacing with a blanking cover).

|

| VSS Output Connector |

|

| Mechanical Speedo Output (will be removed) |

Finally, the connector at the rear of the casing behind the shifter location is for the reverse lock-out solenoid. This is a safety feature and prevents inadvertent selection of reverse gear while the car is travelling forward at great speed; on production cars the solenoid is automatically controlled by the car's ECU to only allow reverse to be selected when the car is stationary.

|

| Reverse Lockout Solenoid Connector |

So how to control the reverse lockout solenoid?

The reverse lock-out is apparently just a spring with a ball-bearing detent. This can be overcome with brute force but clearly is not recommended by Tremec and could lead to damaging the gearbox.

Other solutions suggested involve the use of a microswitch on either the clutch pedal or brake pedal to operate the solenoid - on the basis that you would probably have your foot on one or the other or both when preparing to select reverse gear. The downside is a) the solenoid would operate every time the brake or clutch pedal was pressed so possibly leading to premature wear and failure and b) if the brake or clutch pedal was pressed at 100mph (not unlikely) the solenoid would operate and so it would still be possible to select reverse gear at a high forward velocity, which kind of defeats the object of having it in the first place...

There are several aftermarket manufacturers of a small black box of tricks which simply does the job of the missing OEM ECU and, using the VSS output, will only activate the solenoid when the car is stationary or travelling very slowly (typically less than 3mph). This would probably be the most sensible option. The downside is that these kits cost several hundred dollars (plus good old import duty and shipping).

Fortunately, the CANEMS ECU that I bought as part of my engine package does have the ability to be programmed to operate a switched output based on the VSS output i.e to only operate the solenoid when the car is stationary. Will need a bit of loom surgery to accommodate but in theory, all looks quite straightforward.

The final piece of this story is to obtain the various electrical connectors to join up with those on the gearbox. I bought a kit from Bowler Performance Transmissions in the States; this included all the various connectors each with a short wiring pigtail and a billet blanking plate and bolt for the mechanical speedo output. I ordered online and was quoted some ridiculous price for shipping (more than the price of the kit) but when I rang Bowler they were able to come up with a far cheaper shipping method.

|

| Contents of the Bowler T56 Install Kit |

So looks like I will have some fun when it comes to trying to add these into the wiring loom later but for now, I can get cracking on hooking the gearbox up to my engine and getting closer to installing it in the chassis.